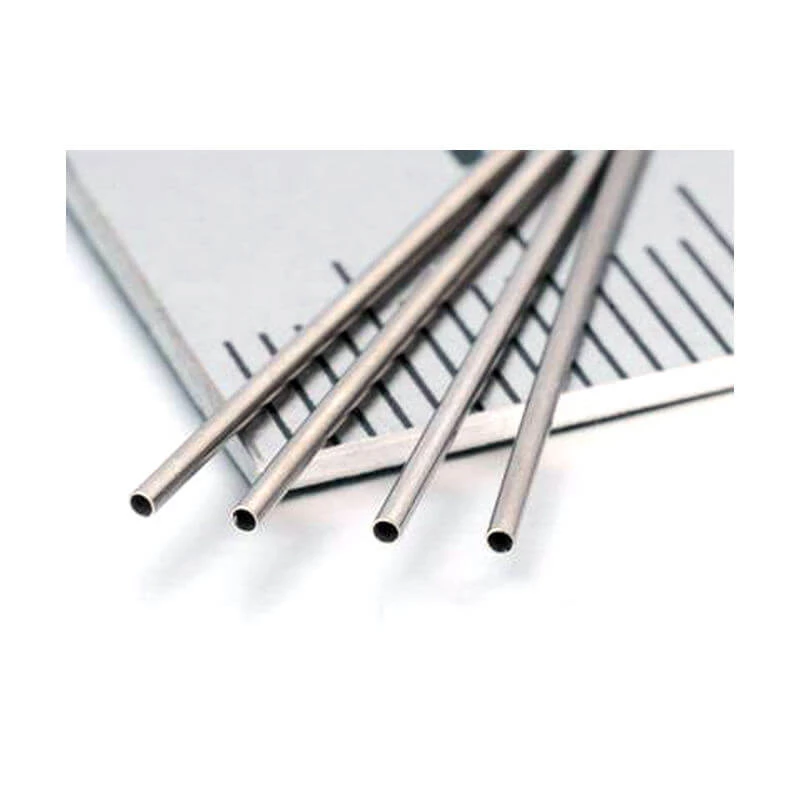

Titanium tubes have the feature of light weight, high strength and superior mechanical properties. Titanium tubes are widely used in heat-exchange equipment, such as tube type heat-exchanger,coiled type heat-exchanger,coil heat-exchanger, condensator,evaporator and transmission pipeline. Many nuclear power industry ues titanium tubes as the unit standard tubes.

| Product Name | Cp1 Cp2 seamless titanium tube titanium pipe |

| Material | Pure titanium and Titanium alloy |

| Titanium Grade | Grade 1—Unalloyed titanium |

| Grade 2—Unalloyed titanium | |

| Grade 3—Unalloyed titanium | |

| Grade 7—Unalloyed titanium plus 0.12 to 0.25 %palladium | |

| Grade 9—Titanium alloy (3 % aluminum, 2.5 % vanadium) | |

| Grade 12—Titanium alloy (0.3 % molybdenum, 0.8 % nickel), | |

| Standard | ASTM B338/ASME SB338, ASTM B337/ASME SB337, ASTM B861/ASME SB861, ASTM B862/ASME SB862,AMS4911,AMS4928 |

| Shape | Round Square Rectangle |

| Type | Seamless/Welded |

| Processing | Seamless titanium tube: Titanium sponge—Compacting electrodes—melting—Forge—Bar billets—Extruding—Rolled—Straightening—Seamless tube |

| Welded titanium tube: Titanium sponge—Compacting electrodes—melting—Forge—Plate billets—Hot rolled—Cold rolled—Titanium scrap—Welded—Welded tube | |

| Surface | Polishing, picking, acid washed, black oxide |

| Application | 1) General service industries (petroleum, food, chemical, paper, fertilizer, fabric, aviation and nuclear |

| 2) Fluid, gas and oil transport | |

| 3) Pressure and heat transmission | |

| 4) Construction and ornament | |

| 5) Boiler heat exchangers | |

| 6) Motorbycle and bike | |

| Material Milling Certificate | According to. EN 10204.3.1 |

| Including Chemical composition and Mechanical property |

| Standard | ASTM B337, ASTM B338, ASTM B861, ASTM B862 |

| Specification | OD5.0-114.0mm x WT0.5-7.0mm x 1000-12000mm |

| OD55mm-914mm x WT1.0-10.0mm x 1000-6000mm | |

| Or according to customer’s requirement. | |

| Payment | T/T, L/C ,Paypal, as your inquiry |

| Technique | Rolled |

| Condition | Annealed(M) |

| Application | a) General service industries (petroleum, food, chemical, paper, fertilizer, fabric, aviation and nuclear) |

| b) Fluid, gas and oil transport | |

| c) Pressure and heat transmission | |

| d) Construction and ornament | |

| e) Boiler heat exchangers | |

| f) motorbycle and bike | |

| Certificate | ISO9001:2008, TUV, EN10204.3.1 |

| Mechanical Properties(>%) | |||||||

| Grade | Tensile Strength(min) | Yeild Strength(0.2% offset)) | Elongation(%) | ||||

| ksi | MPa | Min | Max | ||||

| Ksi | Mpa | Ksi | Mpa | ||||

| 1 | 35 | 240 | 25 | 170 | 45 | 310 | 24 |

| 2 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| 7 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| 9 | 90 | 620 | 70 | 483 | - | - | 15C |

| 12 | 70 | 483 | 50 | 345 | - | - | 18C |

| Mechanical Properties(>%) | |||||||

| Grade | Tensile Strength(min) | Yeild Strength(0.2% offset)) | Elongation(%) | ||||

| ksi | MPa | Min | Max | ||||

| Ksi | Mpa | Ksi | Mpa | ||||

| 1 | 35 | 240 | 25 | 170 | 45 | 310 | 24 |

| 2 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| 7 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| 9 | 90 | 620 | 70 | 483 | - | - | 15C |

| 12 | 70 | 483 | 50 | 345 | - | - | 18C |

Feature:

1.Low Density and High Strength

2.Excellent Corrosion Resistance

3.Good resistance to effect of heat

4.Excellent Bearing to cryogenic property

5.Nonmagnetic and Non-toxic

6.Good thermal properties

7.Low Modulus of Elasticity

Имаме още категории за вас. Ако не можете да намерите продуктите, които искате по-горе, просто попълнете формуляра и ни кажете какви продукти искате да вносите от Китай.