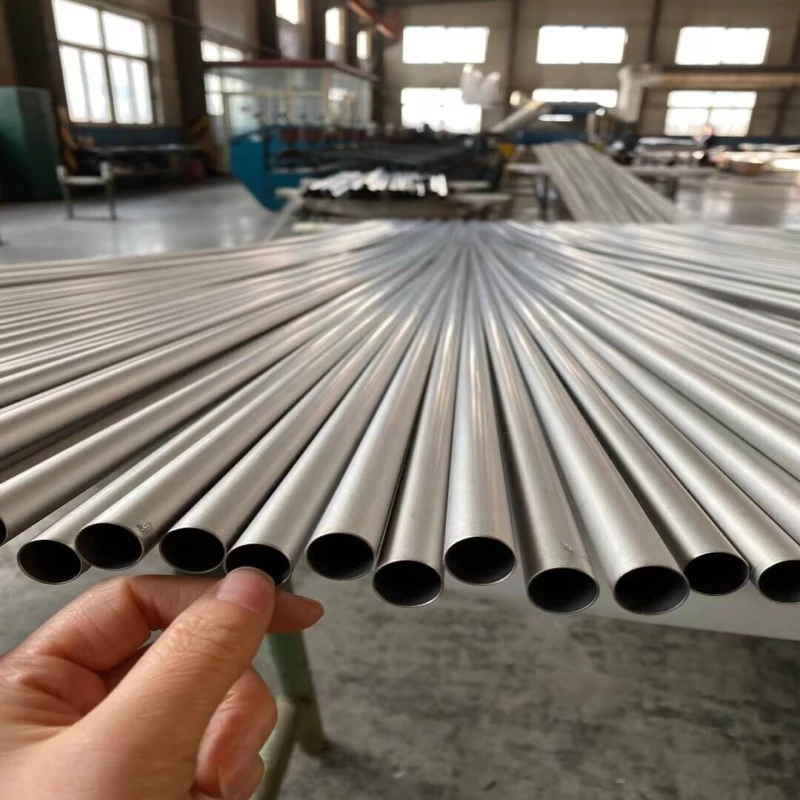

| Materials | N02200, N02201,Ni200, Ni201, N2, N4, N6 |

| Standard | ASTM B161, ASTM B163, ASTM B 725, ASTM B730 |

| In Form | Round, Square, Coil, U shape |

| Size | According To Customer Requirements Or Drawings |

| Length | Standard & Cut Length |

| Surface | Polished or According to Customer's Requirement |

| Packing | Seaworthy Wooden Case |

| Technique | Nickel Welded Pipe, Nickel Seamless Pipe |

Characteristic and Differences

Nickel 200 is commercially pure wrought nickel. It is highly resistant to various reducing chemicals. It can also be used in oxidizing conditions that cause the formation of a passive oxide film, for instance its unexcelled resistance to caustic alkalis. Nickel 200 is limited to service at temperatures below 315℃, because at higher temperatures it suffers from graphitization which results in severely compromised properties. In that circumstance, Nickel 201 is used instead. It has a high Curietemperature and good magnetostrictive properties. Its thermal and electrical conductivities are higher than nickel alloys.

Nickel 201 is the low-carbon version of Nickel 200. Because of its low carbon content, Nickel 201 is not subject to embrittlement by intergranularly precipitated carbon or graphite when exposed to temperatures of 315 to 760℃ for prolonged time if carbonaceous materials are not in contact with it. Therefore, it is a substitute for Nickel 200 in Applications above 315℃. However it does suffer from intergranular embrittlement by sulfur compounds at temperatures above 315℃. Sodium peroxide can be used to change them to sulfates to counteract their effect.

Chemical Composition about nickel rod/bar

| Grade | Element Composition/% | |||||||

| Ni+Co | Mn | Cu | Fe | C | Si | Cr | S | |

| Ni201 | ≥99.0 | ≤0.35 | ≤0.25 | ≤0.30 | ≤0.02 | ≤0.3 | ≤0.2 | ≤0.01 |

| Ni200 | ≥99.0 | /≤0.35 | ≤0.25 | ≤0.30 | ≤0.15 | ≤0.3 | ≤0.2 | ≤0.01 |

Physical properties

| Density | Melting point | Coefficient of expansion | Modulus of rigidity | Modulus of elasticity | Electrical resistivity | |

| Ni200 | 8.9g/cm3 | 1446°C | 13.3 µm/m °C (20-100°C) | 81kN/mm2 | 204kN/mm2 | 9.6μW• cm |

| Ni201 | 1446°C | 13.1µm/m °C (20-100°C) | 82kN/mm2 | 207kN/mm2 | 8.5μW• cm | |

Application High Quality Ni nickel bars for sale

Electroplating, Aluminum Coloring: Its mechanical properties make it excellent for applications in the aerospace and defense industries and in moderately corrosive environments, such as food processing equipment and chemical shipping drums. Construction of the railroad, highway and so on,different kinds of mechanical equipment, electronics, battery, chemical processing, marine engineering

(1) For vacuum coating

(2) For making valves grid, inner components of valves

(3) For making lead, supporting wire

We offers a variety of Nickel Pipe (Nickel Tubing) with high quality to supply our customers. ZHUO HANG XIN is able to supply Nickel Pipe (Nickel Tubing) in accordance with most international standards and special customer requirements. Nickel pipe/tube is produced in a range of outside diameter, wall thickness and various temper conditions to achieve the required mechanical properties and grain size. The mechanical and dimensional characteristics of our products satisfy the most demanding orders that require tight tolerances.

Nickel pipe fittings Product Forms:Nickel elbows,Nickel returns,Nickel reducing tees,Nickel concentric reducers,Nickel lap joint stub ends,Nickel reducers,Nickel couplings,Nickel bushings,Nickel caps

Applications:

Chemical processing, Marine Engineering, Power Generation, Oil and Gas Extraction, Petrochemical processing, Heat Exchangers, Oil Coolers, Radiators, High Capacity Power Plants, Ship Building & Ship Repairs, Condensers, Distiller Tubes, Evaporators, Ferrules etc.

Nickel pipe have good strength and ductility at ordinary temperatures and relatively high strength and other mechanical properties at elevated temperatures. It possess excellent resistance to corrosion by sea water as well as high resistance to erosion corrosion and air-impingement attack.

Testing:

Chemical Composition and mechanical property, Ultrasonic testing, Electric non-destructive testing, Flaring testing, Hydrostatic testing, Flattening testing, Visual surface inspection, Dimensional inspection, Tensile properties inspection.

Value-Added Service:

Draw & expansion as per size & length required

Bending, annealed & pickled, sand blasting & machining, etc

Heat treatment

Test Certificate:

Manufacturer Test Certificate

Laboratory Test Certificate from Govt

Under Third Party Inspection

Имаме още категории за вас. Ако не можете да намерите продуктите, които искате по-горе, просто попълнете формуляра и ни кажете какви продукти искате да вносите от Китай.